BlitzLab offers the following systems, which can be provided to interested users.

Virtual Labtour

Here you have the opportunity to take a virtual Labtour.

Click here or on the Button to start the tour.

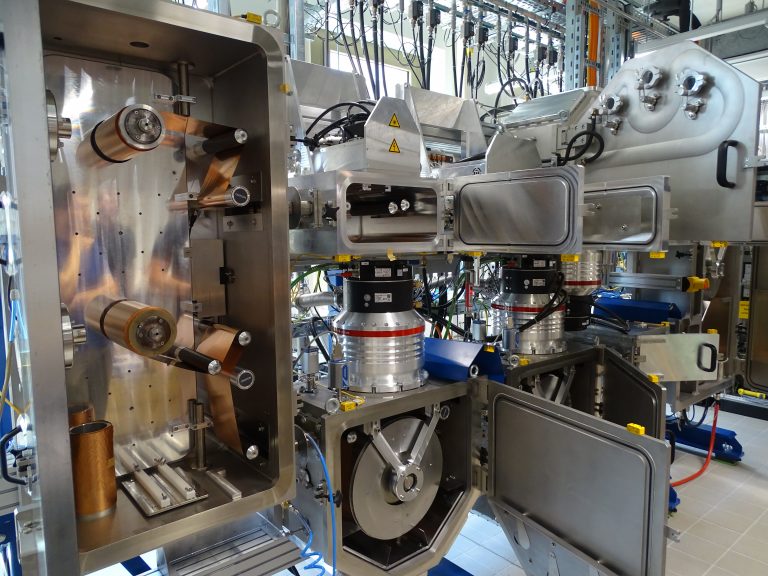

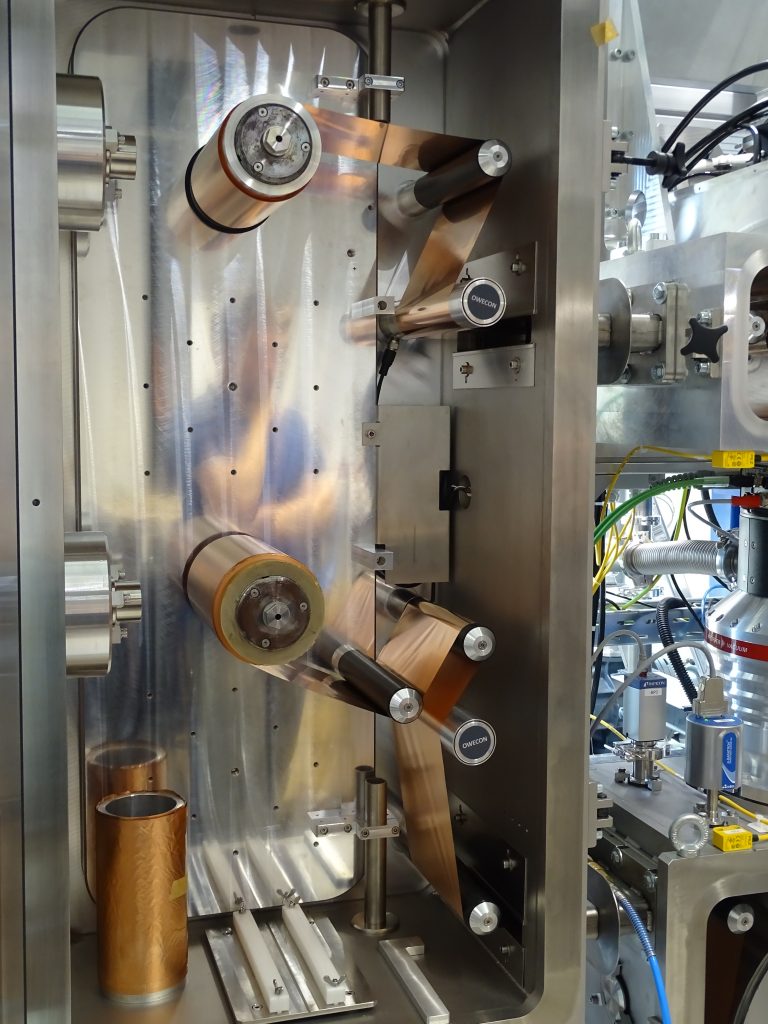

R2R Inkjet and FLA

- Manufacturer: Rovak GmbH

- Modules:

- 1x glovebox workspace

- 1x plasma cleaning

- 1x inkjet

- 2x FLA (Flash Lamp Annealing)

- 1x IR (Infrared) annealing

- Operating modes: sheet-to-sheet (S2S), roll-to-roll (R2R)

- Substrate size S2S: up to 300 x 200 mm2

- Parameters R2R:

- roll width: 180 mm

- film thickness (metal): 10 – 40 µm

- film thickness (plastic): 10 – 150 µm

- Flash mode:

- single lamp

- single pulse and multi-flash up to 10 Hz

- Gas: Argon, Atmosphere

- Inkjet: Fujifilm Dimatix SAMBA G3 (compatible with FUJIFILM DMP-2850)

RTP 1200

(Location: ZeHS, TU Bergakademie Freiberg)

- Manufacturer: Von Ardenne GmbH

- Substrate size: up to 1200 mm x 1200 mm

- Transportation speed: up to 1 m/min

- Annealing gas: atmosphere

- Flash mode:

- lamp field 300 x 1700 mm

- single pulse

- Pulse duration: ~ 0.6 ms

- Energy density: up to 13 Jcm-2

FLA01

- Manufacturer:

- in-house development (flash division)

- Rovak GmbH (energy storage system)

- Substrate size: up to 100 mm in diameter

- Annealing gases: nitrogen, argon, oxygen, forming gas

- Flash mode:

- lamp field

- single pulse

- combined pulse

- Pulse times: 0.65 – 20 ms

- Preheating: up to 700°C

- Energy density: up to 200 Jcm-2

Sputter FLA

- Manufacturer: Rovak GmbH

- Substrate size: up to 300 x 200 mm2

- Annealing environment: vacuum, nitrogen, argon, oxygen

- Flash mode:

- single lamp

- single pulse

- multi-flash up to 10 Hz

- Pulse duration: 0.33 – 3 ms

- Energy density: up to 30 Jcm-2 per pulse

Flash Cube

- Manufacturer:

- in-house development (flash division)

- Rovak GmbH (energy storage system)

- Substrate size: up to 150 mm

- Annealing environment: nitrogen, argon, oxygen, forming gas, vacuum

- Flash modes:

- lamp field

- single pulse

- combined pulse

- Pulse duration: 0.65 – 20 ms

- Energy density: up to 160 Jcm-2

Laser annealing: COMPexPRO 201

- Manufacturer: Coherent

- Wave length: 308 nm

- Max. energy per pulse: 500 mJ

- Pulse duration: 30 ns, 10 Hz

- R2R coil coating

(TU Bergakademie Freiberg)

- Manufacturer: ROVAK GmbH

- Modules:

- 1x plasma cleaning

- 2x sputter deposition

- 1x EB‑PVD

- 3x FLA

- 1x IR-Tempering

- Parameters R2R:

- foil width: up to 180 mm

- foil thickness: 10 – 100 µm

- Gas: argon, nitrogen, oxygen

- Flash modes:

- single lamp

- single pulse

- multi‑flash up to 10 Hz

- Pulse duration: 0,3 to 10 ms

- Energy density: > 40 J/cm² per pulse

For more informationen please click here.

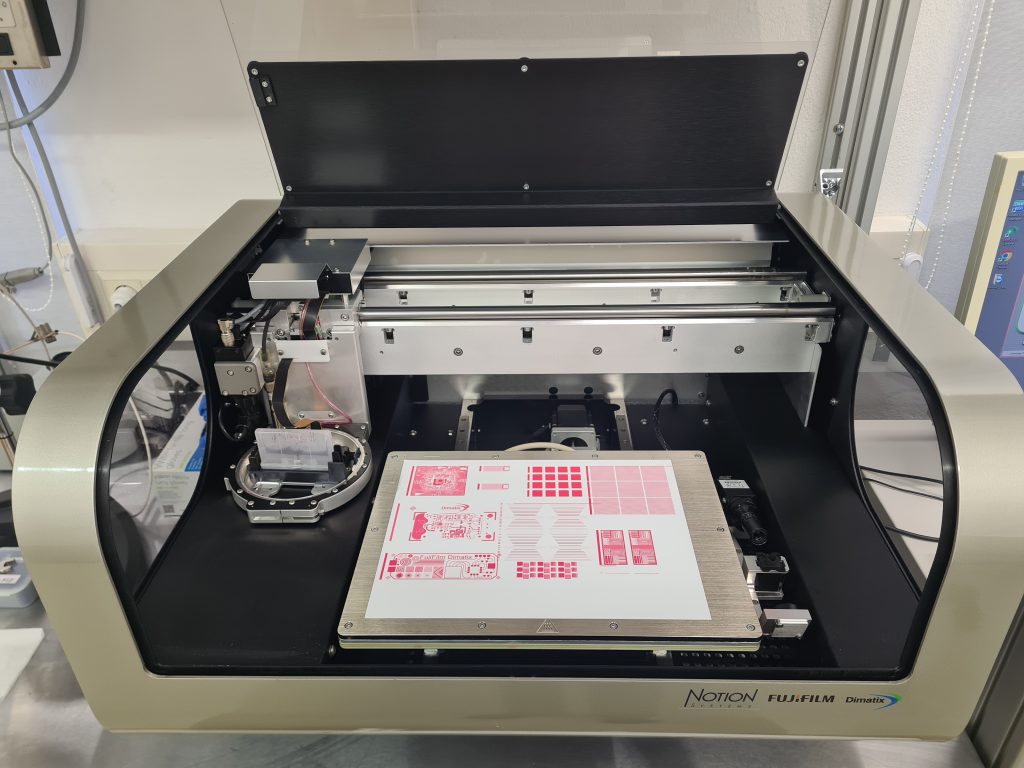

Inkjetprinter DMP-2850

- Manufacturer: FULIFILM Dimatrix

-

Movable xyz-table

-

Printable area ~ A4 format

-

Substrate thickness < 0.5 – 25 mm

-

Repeatability: ± 25 μm

-

Min. drop size ~ 30 µm (native drop volume 2.4 pL)

-

Inks: metal, semiconductor, ceramics, biopolymers, etc.

-

Printing head substrate heating: up to 60°C

-

Cost-effective, piezo-based inkjet printer cartridges

-

Ink capacity: 1.5 ml

Glovebox

- Manufacturer: GS Systemtechnik GmbH

-

For the assembly of Lithium- Ion- Battery cells

-

Argon atmosphere: Oxygen and water < 0.5 ppm

- For two Working places

Virtual Labtour

Here you have the opportunity to take a virtual Labtour.

Click here or on the Button to start the tour.