In photovoltaics, FLA can help to lower production costs by replacing more costly thermal treatments and by the possibility to use temperature-sensible substrates. In the case of multicrystalline solar cells, it was shown that FLA can simultaneously activate implanted phosphorous, recrystallize Si,

and suppress the diffusion of metal impurities and their activation. In combination with ion implantation, FLA reduces the solar cell fabrication steps by two leading to significant cost reduction [1].

Thin film solar cells are usually deposited on glass and flexible substrates, which define the thermal budget that can be applied during solar cell fabrication. In the case of flexible polymer-based substrates, the maximum temperature is limited to about 300 °C, whereas glass substrates tolerate annealing temperatures in the range of 500 °C.

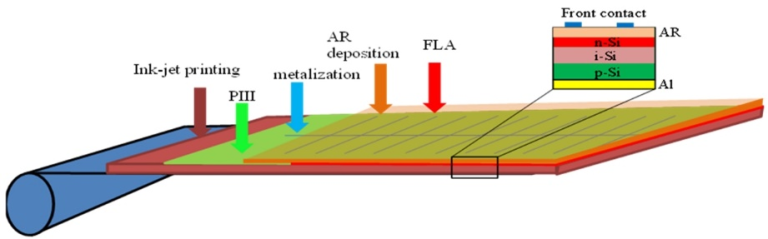

However, the maximum temperature can be significantly increased if the annealing time is very short as in case of flash lamp annealing. Fig. 1 shows an example of a Roll-to-Roll (R2R) process where FLA can be used for both the recrystallization of the thin Si film and the dopant activation [2].

Sources:

[1] S. Prucnal et al., J. Appl. Phys. 111, 123104 (2012)

[2] L. Rebohle, S. Prucnal, D. Reichel: Flash Lamp Annealing – from Basics to Application, Springer (2019)