Ge-based microelectonics

The ongoing miniaturization of microelectronic circuitries leads to an increasing need for alternative semiconductors. One of these materials is germanium featuring an electron and hole mobility which are 2.5 and nearly 4 times higher than that of Si, respectively. The Processing of Ge is, inter alias, challenging for

(i) achieving an n-type doping level as high as possible

(ii) the fabrication of suitable contacts for n-type Ge

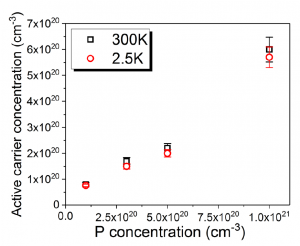

Fig. 1: Active carrier concentration in phosphorous-doped Ge after FLA [1]

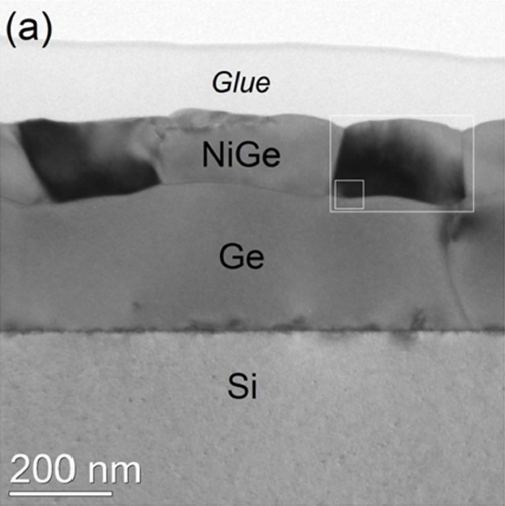

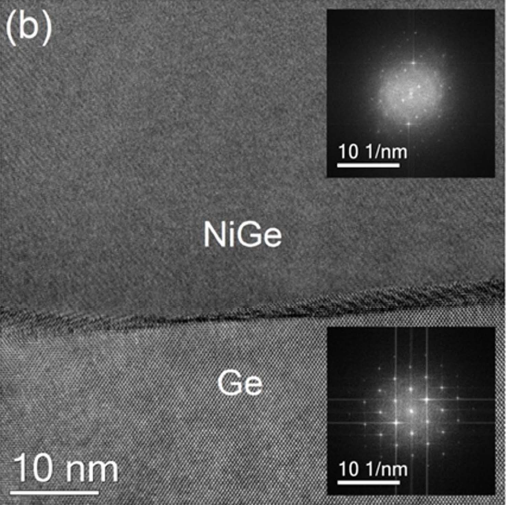

FLA can be used to fabricate a good Ohmic contact on Ge. Fig. 2 shows a TEM image of a NiGe contact on a Ge-on-insulator substrate. In the present case Ge was implanted by phosphorous, followed by the deposition of Ni. The subsequent FLA served for both the activation of dopants and the contact formation, which

Fig. 2: TEM image of a phosphorous-doped GeOI substrate with a NiGe contact after FLA (a) and detail view of the interface NiGe to Ge [2]

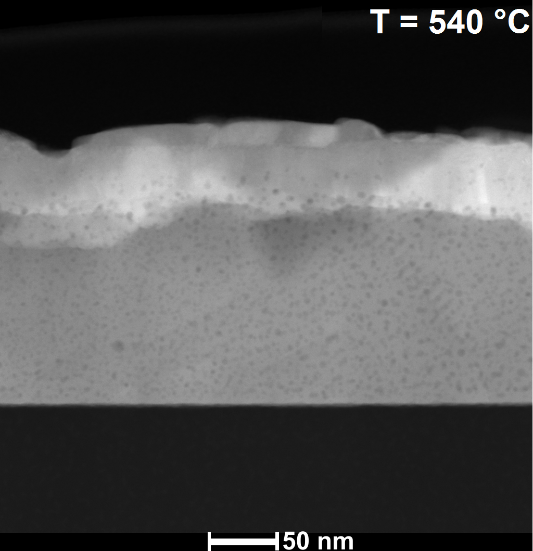

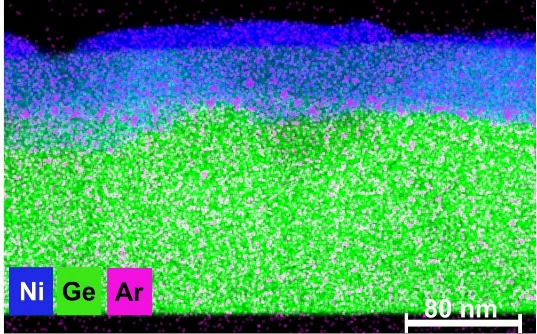

FLA is also suitable for the formation of NiGe contacts on thin, poly-crystalline Ge layers, as they are used e.g. in the field of printed or flexible electronics. Although the interface between NiGe and Ge (Fig. 3) is more diffuse compared to mono-crystalline Ge (Fig. 2),

a specific resistivity of ca. 14 ·10−6 Ωcm for NiGe is achieved. This value is comparable with literature values, which have been obtained by rapid thermal processing (RTP) or laser annealing.

Fig. 3: TEM image (left) and corresponding element distribution as measured by EDX (right) for 30 nm Ni on 160 nm Ge after FLA annealing [3].

Quellen

[1] Prucnal et al., J. Appl. Phys. 125 (2019) 245703

[2] Prucnal et al., Semicond. Sci. Technol. 32 (2017) 115006

[3] Begeza et al., nanomaterials 10 (2020) 648