Flash Lamp Annealing (FLA) was developed in the environment of the semiconductor industry. Over the course of the last years, a wide variety of application fields opened up, such as:

• thin semiconductor layers, e.g. for sensors and photovoltaics

• transparent oxides, e.g. Indium-tin-oxide

• energy materials, e.g. for battery technology

• printed electronics

• FLA-assisted deposition, e.g. flash-ALD or sputter-FLA

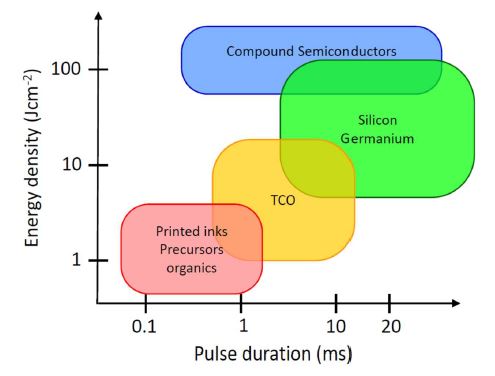

Depending on the application, the energy density (intensity), the pulse length, the repetition rate, the tempering atmosphere (air, inert gas, vacuum, etc.), the lamp arrangement and handling vary. Fig. 1 shows electrical performance parameters for typical FLA applications.

When it comes to handling, a distinction can be made between R2R (roll-to-roll) and S2S (sheet-to-sheet) applications, in which case the substrate is usually cured as a whole using a lamp field. The following table shows a brief comparison between the two methods:

| S2S | R2R | |

|---|---|---|

| Energy density per pulse | medium / high | low |

| Pulse length | ms-range | < 1 ms |

| Flash frequency | low | medium / high |

| Lamps | Lamp field | 1 or 2 lamps |

| Irradiated area | whole substrate | strip-shaped area |

| Typical applications | Semiconductor industry thin semiconductor layers, transparent oxide | printed electronics, energy materials thin semiconductor layers, transparent oxide |